In this new time of logical instrumentation and analyzers, the requirement for fluidics the board at an undeniably exact rate has overshadowed the normalized pumping strategies utilized previously. The diaphragm pump is a misleadingly straightforward structure. A diaphragm, or film, is situated in a pumping chamber, normally structure fitted to accomplish effective gas or smooth motion. The film can be made of thermoplastic, elastic. The adaptability is not as significant as the materials capacity to withstand against high temperatures, harsh or acidic synthetic concoctions, or acidic fumes. The diaphragm must have the option to run inconclusively without worry of overheating or general wear over brief periods. The valve framework should likewise follow certain rules for security and stream control. The valves must be made of materials that can likewise withstand conceivable dangerous substances, and not lose their usefulness in the presentation to inordinate warmth or cold.

The valve timing must be proficient and cause a consistent progression of air, liquid, or gas without interference or floods. Some diaphragm pumps are utilized for the negative weight, as in vacuum frameworks utilized in science or hematology analyzers. Supplies are utilized to keep up a steady vacuum after the pump has arrived at the necessary weight, so the pump is possibly actuated now and again when the negative weight arrives at bothersome levels. The diaphragm pump must withstand on-and-off activity at various occasions, and the motor must be a brisk reaction electric with auto-shutdown if overheating is reached. This is phenomenal for the activity of a few instruments that require positive weight in their repositories. Finding the pumping framework for the analyzers and other instrumentation of the research facility can be simply an issue of how you work fluidics or fluid dealing with, or what kind of investigation is overwhelming in the lab.

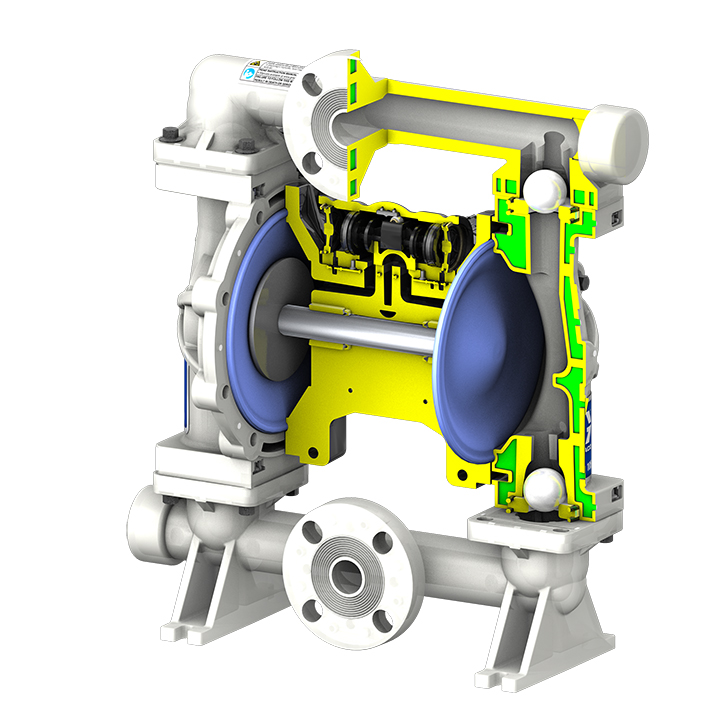

Probably the best technique for liquid administration is the diaphragm pump. This is one of the principle purposes behind its utilization in different mechanical applications. It is likewise utilized in fake hearts because of its adaptable structures and other gainful highlights. These pumps incorporate two sorts of actuators which work in an unexpected way. The stream pace of these pumps relies upon its factors and the rise. Each pump has explicit stream rates and working levels. In any case, this level may increment with the adjustments in the height levels. A diaphragm pump can give significantly more weight and extreme vacuum to deal with pretty much any need and click here to gather more information. These bigger, powerful units have two diaphragms working pair, with the goal that the stream rate through cylinders is steady and controlled. With measures and help valves, there can be no uncertainty about the exhibition of these adaptable and accuracy pumping frameworks. Diaphragm pumps are the frameworks of decision for some examination and clinical research centers the world over.